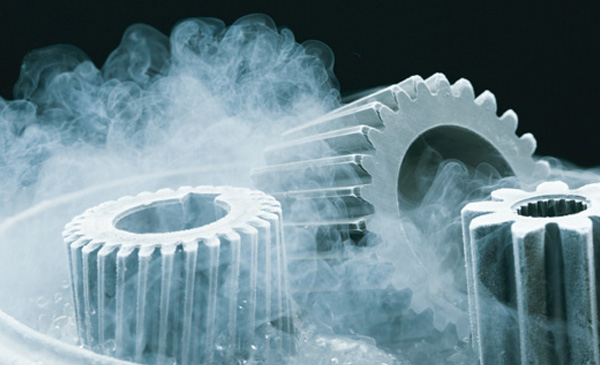

Cryogenic Treatment

- Home

- Cryogenic Treatment

Cryogenic Treatment

Many cases are reported where a certain amount of the residual austenite, often a very considerable amount, still remains in the structure of a hardened steel. in most cases this residual austenite is considered as an undesirable phenomenon, for the following reasons:

- As the austenite is much less hard than martensite, the hardness of a hardened steel containing residual austenite is well below the maximum

- As has been just pointed out, the residual austenite brings about a gradual, spontaneous change in dimensions of articles treated

- As the austenite is non magnetic, its presence in steel magnets decreases the magnetic induction and, consequently, the lifting power of magnets.

- The residual austenite remains in the steel structure because for many steels the austenite completes its transformation into martensite at temperatures well below zero. this suggests a simple method of removing residual austenite from the structure of a hardened steel, consisting of cooling it to a temperature well below zero, i.e., of subjecting it to the sub-zero treatment. this is the method proposed by Professor A.P. Gulyaev in 1937.

Review from our clients

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eius mod

tempor incididunt ut labore et dolore magna aliqua.

Best Consulting Firm

Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidu laboreetde magnam aliquam quaerat voluptatem.

Alexa Reid

Synopsis

Nice People

Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidu laboreetde magnam aliquam quaerat voluptatem.

Alva Goldhammer

Synopsis

Nice People

Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidu laboreetde magnam aliquam quaerat voluptatem.

Alva Goldhammer

Synopsis

Nice People

Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidu laboreetde magnam aliquam quaerat voluptatem.

Adam McDonald

Synopsis

Advantages of the cryogenic treatment

- It makes the process of machining a smoother and an easier process.

- Cryogenic treatment results in increasing the electrical properties of the material.

- It also helps to reduce the resistance of the metal.

Following are the applications of the cryogenic hardening

- In Automotive industry: cryogenic hardening is mostly used in case of the applications related to automotive industry.

- Applications in the mechanical industry: It includes different motors, pumps, washers as well as small bolts.It is mostly used in cutting tools industry for manufacturing cutters, blades, knives, etc.

- Cryogenic hardening is also find its use in the Aerospace and defense sector. It is used in landing systems and controlling systems.